Selection of shape and diameter should be based on the work piece, and the operation to be performed.

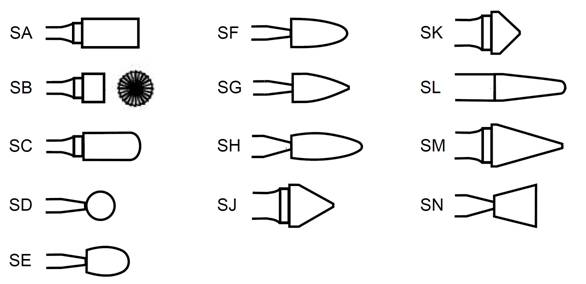

Selection of shape and diameter should be based on the work piece, and the operation to be performed.  Burs have 13 basic shapes:

Burs have 13 basic shapes:

Burs come in 7 kinds of flute style as following.

Burs come in 7 kinds of flute style as following.

Selection of cut would be based on the material, and finish required.

Selection of cut would be based on the material, and finish required. | Material | 6 | 3 | 1 | 3SP | 4 | 2 | 5 |

| Aluminum |  |

||||||

| Brass, Bronze Copper |  |

|

|

||||

| Carbon Fiber |  |

|

|||||

| Fiberglass |  |

||||||

| Cast Iron |  |

|

|

||||

| Plastics |  |

|

|||||

| Hard Rubber |  |

||||||

| Steel, 40-55 Rc |  |

|

|

|

|

||

| Steel, 55-60 Rc |  |

|

|

|

|

||

| Steel, Carbon |  |

|

|

||||

| Steel, Nickel Chrome |  |

|

|

|

|||

| Steel, Stainless |  |

|

|

|

|||

| Steel, Weldments |  |

|

|

||||

| Titanium |  |

|

|

||||

| Zinc |  |

| Grade | Cobalt | HRA | HRC | Density (ISO 3369) |

Transverse rupture strength (ISO 3327) |

| K30 | 8% | 89.3-89.5 | 74.3-74.6 | 14.8 | 2000 |

| K25 | 7% | 89.5-90.5 | 74.6-77 | 14.9 | 2650 |

| K20 | 6% | 90.1-91.5 | 76.2-78.4 | 14.7- 15 | 1800 |

| Material of work- piece |

RECOMMENDED ROTARY SPEEDr/min (Rotary speed = the below number x1000) | |||||||||

| Dia 3mm | Dia 6mm | Dia 8mm | Dia 10mm | Dia 12mm | Dia 16mm | Dia 20mm | Dia 25mm | |||

| Steel, cast steel | Non- hardened,non- heat treated steels |

Aggressive grinding | 60000- 95000 |

32000- 48000 |

24000- 36000 |

19000- 29000 |

16000- 24000 |

12000- 18000 |

10000- 14000 |

8000- 11000 |

| Fine grinding | 48000- 64000 |

24000- 32000 |

18000- 24000 |

14000- 19000 |

12000- 16000 |

9000- 12000 |

7000- 1000 |

6000- 8000 |

||

| Hard non-ferrous metals | Aggressive grinding | 27000- 37000 |

13000- 19000 |

10000- 14000 |

8000- 11000 |

7000- 9000 |

5000- 7000 |

4000- 6000 |

3000- 4000 |

|

| Fine grinding | 37000- 48000 |

19000- 24000 |

14000- 18000 |

11000- 14000 |

9000- 12000 |

7000- 9000 |

6000- 7000 |

4000- 6000 |

||

| Stainless steel (INOX) | Rust and acid-resistant steels | Aggressive grinding | 32000- 48000 |

16000- 24000 |

12000- 18000 |

10000- 14000 |

8000- 12000 |

6000- 9000 |

5000- 7000 |

4000- 6000 |

| Fine grinding | 37000- 48000 |

19000- 24000 |

14000- 18000 |

11000- 14000 |

9000- 12000 |

7000- 9000 |

6000- 7000 |

4000- 6000 |

||

| Aggressive grinding | 32000- 48000 |

16000- 24000 |

12000- 18000 |

10000- 14000 |

8000- 12000 |

6000- 9000 |

5000- 7000 |

4000- 6000 |

||

| Fine grinding | 37000- 53000 |

19000- 27000 |

14000- 20000 |

11000- 16000 |

9000- 13000 |

7000- 11000 |

6000- 8000 |

4000- 6000 |

||

| Cast iron | Grey cast iron, white cast iron | Aggressive grinding | 60000- 95000 |

32000- 48000 |

24000- 36000 |

19000- 29000 |

16000- 24000 |

12000- 18000 |

10000- 14000 |

8000- 11000 |

| middle grinding | 48000- 64000 |

24000- 32000 |

18000- 24000 |

14000- 19000 |

12000- 16000 |

9000- 12000 |

7000- 1000 |

6000- 8000 |

||

| Fine grinding | 53000- 64000 |

27000- 32000 |

20000- 24000 |

16000- 19000 |

13000- 16000 |

10000- 12000 |

8000- 10000 |

6000- 8000 |

||